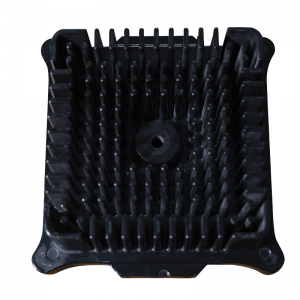

ʻO ka heatsink maʻamau i hoʻolei ʻia no ka Radiator

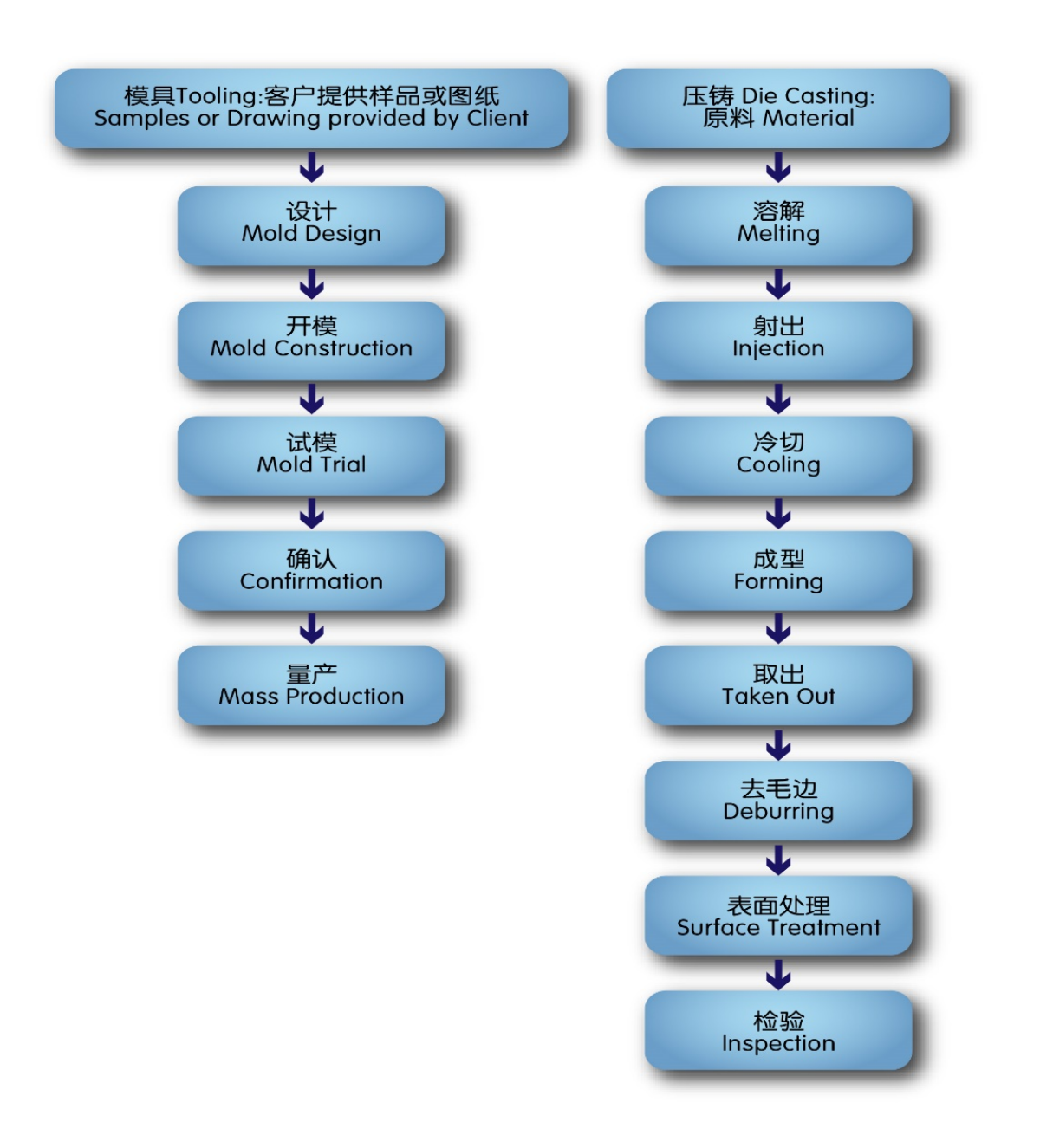

Ke kaʻina hana o ka hoʻomehana wela

Hoʻolālā mea hana

Hoʻolei make kiʻekiʻe

ʻokiʻoki

Ka wehe ʻana i nā ʻōpala

Ka pahū ʻana one

Hoʻopili ʻili

Uhi Pauka

Ke kuʻi ʻana a me ka mīkini ʻana o CNC

Hoʻokomo helical

Ka mālama ʻana i ka ʻili

1. Hoʻomake kemika

2. Ke pena ʻana

3. Electrophoresis

4. Anodizing

5. Uhi pauka

Nā poho wela make

He kūpono loa nā poho wela make inā makemake ʻoe i kahi poho wela alumini i hoʻolālā ʻia. Hana ʻia lākou ma ke koi ʻana i ka alumini wai ma lalo o ke kaomi kiʻekiʻe i loko o nā ʻōmole kila. He mea kaulana ka poho wela make ma ka mākeke no ka mea ua hana ʻia mai ka hui alumini. ʻO kēia ka mea makemake nui ʻia no ka poho wela make. He kūpono kēia mau kaʻina hana make e hoʻokō i kēlā me kēia koi papahana a hana wikiwiki ʻia ka hana ʻana.

ʻO ka manawa alakaʻi wikiwiki he 35-40 mau lā wale nō

Hana kiʻekiʻe ma nā ʻili anodized

Nā ana paʻa kiʻekiʻe i kāohi ʻia i loko o +/- 0.05mm

Kōkua nā ʻenekinia i ka hoʻopau ʻana mai ka hoʻolālā a i ka hana ʻana

Nā Pōmaikaʻi o nā Pūpū Wela Die Cast

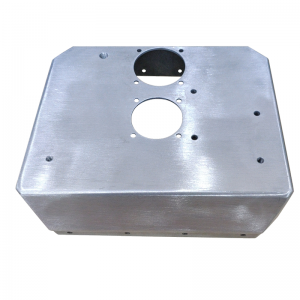

Ke hoʻohālikelike ʻia me nā ʻano hana ʻē aʻe, hāʻawi ka die casting i nā pono penei:

1. Hana i nā ʻano 3D paʻakikī i hiki ʻole ke hana ʻia ma ka extrusion a i ʻole ka forging

hiki ke hoʻohui ʻia ka lua wela alumini, ka mōlina, ka hale, ka pā a me nā mea hoʻopaʻa i loko o kahi hoʻolei hoʻokahi

2. Hiki ke ʻeli ʻia nā lua i loko o ka hoʻolei make

3. Ka nui o ka hana a me ke kumukūʻai haʻahaʻa

4. Nā hoʻomanawanui paʻa

5. Paʻa ka nui

6. ʻAʻole koi ʻia ka mīkini lua

E hoʻolako i nā ʻili pālahalaha loa (maikaʻi no ka hoʻopili ʻana ma waena o ka lua hoʻomehana a me ke kumu)

Nā helu kūpaʻa i ka palaho mai ka maikaʻi a i ke kiʻekiʻe

Ke kahe o ke kaʻina hana Kingrun

Ke hoʻohālikelike ʻia me nā ʻano hana ʻē aʻe, hāʻawi ka die casting i nā pono penei:

1. Hana i nā ʻano 3D paʻakikī i hiki ʻole ke hana ʻia ma ka extrusion a i ʻole ka forging

Hiki ke hoʻohui ʻia ka poho wela, ka mōlina, ka hale, ka pā a me nā mea hoʻopaʻa i loko o hoʻokahi hoʻolei ʻana

2. Hiki ke ʻeli ʻia nā lua i loko o ka hoʻolei make

3. Ka nui o ka hana a me ke kumukūʻai haʻahaʻa

4. Nā hoʻomanawanui paʻa

5. Paʻa ka nui

6. ʻAʻole koi ʻia ka mīkini lua

E hoʻolako i nā ʻili pālahalaha loa (maikaʻi no ka hoʻopili ʻana ma waena o ka lua hoʻomehana a me ke kumu)

Nā helu kūpaʻa i ka palaho mai ka maikaʻi a i ke kiʻekiʻe

Palekana EMI a me RFI maikaʻi loa